Quality Αssurance

At Forlabels, quality control starts with well-trained people, managers with a strong sense of responsibility and strict observance of quality control standards, to reach goes all the way to investments in a high-tech quality control system that is constantly being upgraded.

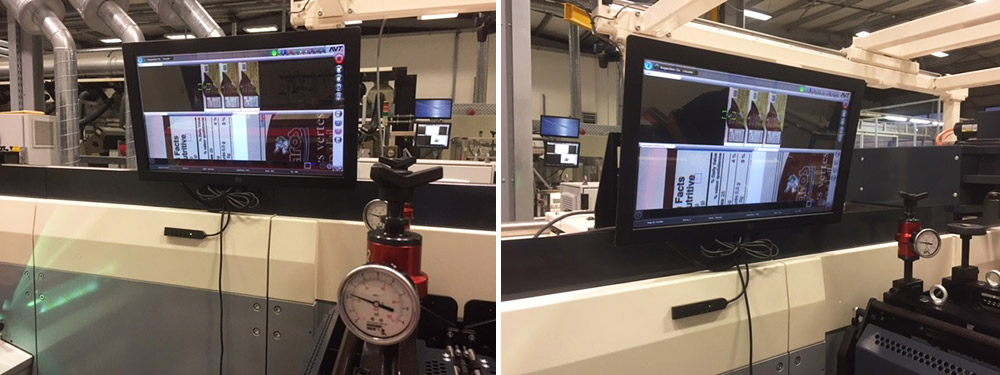

The quality control system the Company uses was made by AVT, the largest programmer and manufacturer of automated control systems for packaging and printing applications in the world.

The system, equipped with ultra-high-speed cameras and image processing software monitors the work flow from proofreading, to image inspection, materials, and bar codes, and can detect even the slightest mistake.

This minimises the risk of even one label reaching the client if does not meet specifications to a T.

This is custom heading element

The main concern and general objective of our policy is the continuous improvement of our business performance and the creation of an added value for our customers, making use of the rapid technological developments in the dynamic field of labels and flexible packaging materials.

In particular, the individual objectives of our company with regard to Food Quality and Safety are:

- The continuous improvement of our business performance

- Ensuring the safety of the manufactured products

- The continuous development of our human resources

- The optimization of our customers’ satisfaction

In order to achieve the aforementioned, FORLABELS has established, implements and constantly improves a Unified System of Food Quality and Safety Administration, which complies with the International Standards ISO 9001:2015 and ISO 22000:2005. The Company’s Board estimates that the System of Food Quality and Safety Administration is an essential means of strengthening its Business position owing to:

- The continuous improvement of the quality of our products and services

- Cost reduction

- Efficient in the organization

- The promotion of innovation

- The better working environment

The framework and mechanism for defining and reviewing our Quality goals and objectives is set in the regular reviews of the System from the Company’s Board.

The continuous improvement of our quality performance and the prevention of non-compliances presuppose the realization and the systematic control of both every individual process and as a whole.

The way we use to monitor the processes demands:

- An explicit designation of responsibilities for both every process and every job position.

- Written documentation (Procedures, Work Instructions, Control Instructions etc), where it is needed.

- Continuous monitoring of the recognized processes.

- Data records which prove the Quality of the services offered.

- The development of programs aiming at achieving the Food Quality and Safety objectives.

- A procedure through which the company is to be learning through the mistakes made, so that they are not to be repeated (Corrective Actions) and to continuously improve its operations, in addition to shaping a framework towards error prevention.

- Systematic investments on modern building infrastructure, machinery and operating systems.

- Specified raw materials and manufactured products standards.

- Ensuring that its suppliers comply with certain food quality and safety specifications.

- Identifying, evaluating and addressing the risks associated with the quality and safety of the manufactured products.

The Company Board has identified the threats and opportunities associated with its proper and effective operation and are committed to:

- Compliance with the regulatory requirements regarding its products.

- Understanding of their customers’ needs and expectations and each and every involved part in general.

- Continuous improvement of the efficiency of the Food Quality and Safety System.

- Immediate response to its customers’ demands and compliance with the commitments and obligations of the company, as these are defined through the relevant contracts.

- Communication of the objectives and goals with the employees and encouragement of the staff for participation and contribution towards continuous improvement.

The Unified Administration System is reviewed at regular intervals regarding both its suitability and effectiveness and is to be amended whenever needed and the personnel is simultaneously to be notified.

Avgerinos Chatzichrisos

Vasilis Chatzichrisos